Author: Roydon Gilmour

Stainless steel wire rope looks great…..well when new or when well maintained. But there is nothing that looks worse than a balustrade full of rusty wire rope. So how do you make sure it keeps looking good?

3 steps:

Let me explain. Firstly:

1. Make sure you use a high standard of 316 stainless steel wire rope:

Not all 316 wire rope is made equal. There are different ways it can be made, some manufacturing techniques will result in excellent performance and some will not.

So what works? Well it is impossible to tell by looking at the wire but certain production techniques can significantly reduce the ability of the stainless wire to resist tea-staining, these include:

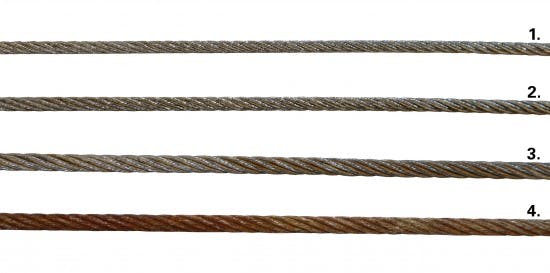

To illustrate the difference in performance of stainless steel wires, we have conducted an experiment. Simulating an extreme corrosive environment, we left samples of wire in a highly concentrated salt-water solution for 3 months. The performance of the stainless steel was further tested given the availability of oxygen was significantly reduced (being in water), therefore reducing its ability to produce the protective chromium oxide layer that stainless steel requires to inhibit corrosion.

So to the results:

Then:

2. Apply Prolan liquid/spray to the wire rope to keep salt or other contaminants at bay.

Prolan is a Lanolin product from Sheep’s wool which can be wiped on the wire rope as a liquid with a soft cloth. It will provide an excellent protective barrier helping keep contaminants off. This is especially important as the wire rope structure naturally provides crevices for salt to get trapped in between the strands.

And finally:

3. Regularly clean it.

Very simple; give it a wash down with soapy water. Cleaning frequency will depend on your location but if you are anywhere near a surf beach, regular cleaning and application of Prolan will be essential to keeping the wire well maintained and looking great.

So getting the right 316 wire rope is very important – choose a proven/reliable supplier for your product and then with a small amount of elbow grease you can keep it looking great!

Roydon Gilmour was previously employed with a Civil Engineering firm for 15 year designing, testing and sourcing components. For the last 5 years, he has been the Technical Manager at Anzor Fasteners helping customers with their Meshnet, Balustrades and other Architectural inquiries.

Roydon is a Certified ISSF Stainless Specialist and is a current NZ Stainless Steel Development Association (NZSSDA) member. He was also a previous board member for the NZSSDA. Check out Roydon on his LinkedIn profile for more information.

Anzor's 2024 Christmas Opening Hours

Build Your Deck Faster With Our Decking Screw Calculator

Do it once, do it right with Fischer FBS II Concrete Screw Bolts.

To receive useful info and product updates add your details below